Domain Expertise

With more than 30 years' experience in facility and process equipment design and manufacturing, Dakota has a uniquely comprehensive understanding of gas delivery systems from the gas source to the process chamber. We leverage this domain expertise to provide emerging technologies partners design insights and manufacturing best practices to further their process technology. Our domain expertise manifests in three core areas:

Designing for Manufacturing Scalability

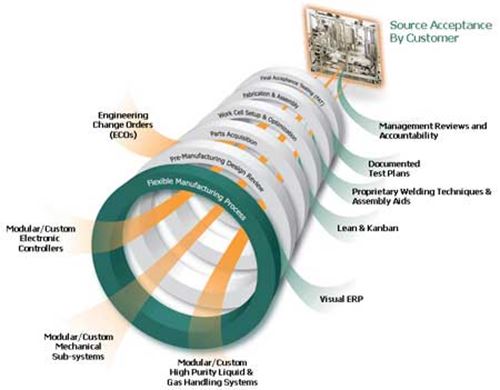

We work with clean energy technology customers from prototype to production. In addition to our materials delivery expertise and manufacturing excellence, including diligent ERP documentation and supply chain management, Dakota’s production-ready facility features class 100 & 1000 clean rooms, clean assembly space, and final test bays to run complete equipment testing and validation before we ship.

Emerging Tech Manufacturing

Dakota works with customers to advance their emerging technologies manufacturing from prototype to production. In addition to our extensive domain expertise and manufacturing excellence, including diligent ERP documentation and supply chain management, Dakota’s production-ready facility features class 100 & 1000 clean rooms, clean assembly space, and final test bays to run complete equipment testing and validation before we ship.

Learn more about a Dakota partnership and the Dakota Difference.

Product Lifecycle Manufacturing Partnership

Dakota partners with our customers throughout the product lifecycle. From building prototype equipment to testing and validating at Alpha and Beta sites to full scale manufacturing and next generation development, we help our customers optimize their product lifecycle to maximize profits and remain dominant in their space.

Watch this video to learn more about Product Lifecycle Manufacturing Partnerships